In addition to the high technical and production performance at Colosio, we aim to reduce the operating costs and environmental impact of our die-casting machinery as much as possible. This is why we have designed and implemented the system to ensure maximum energy savings.

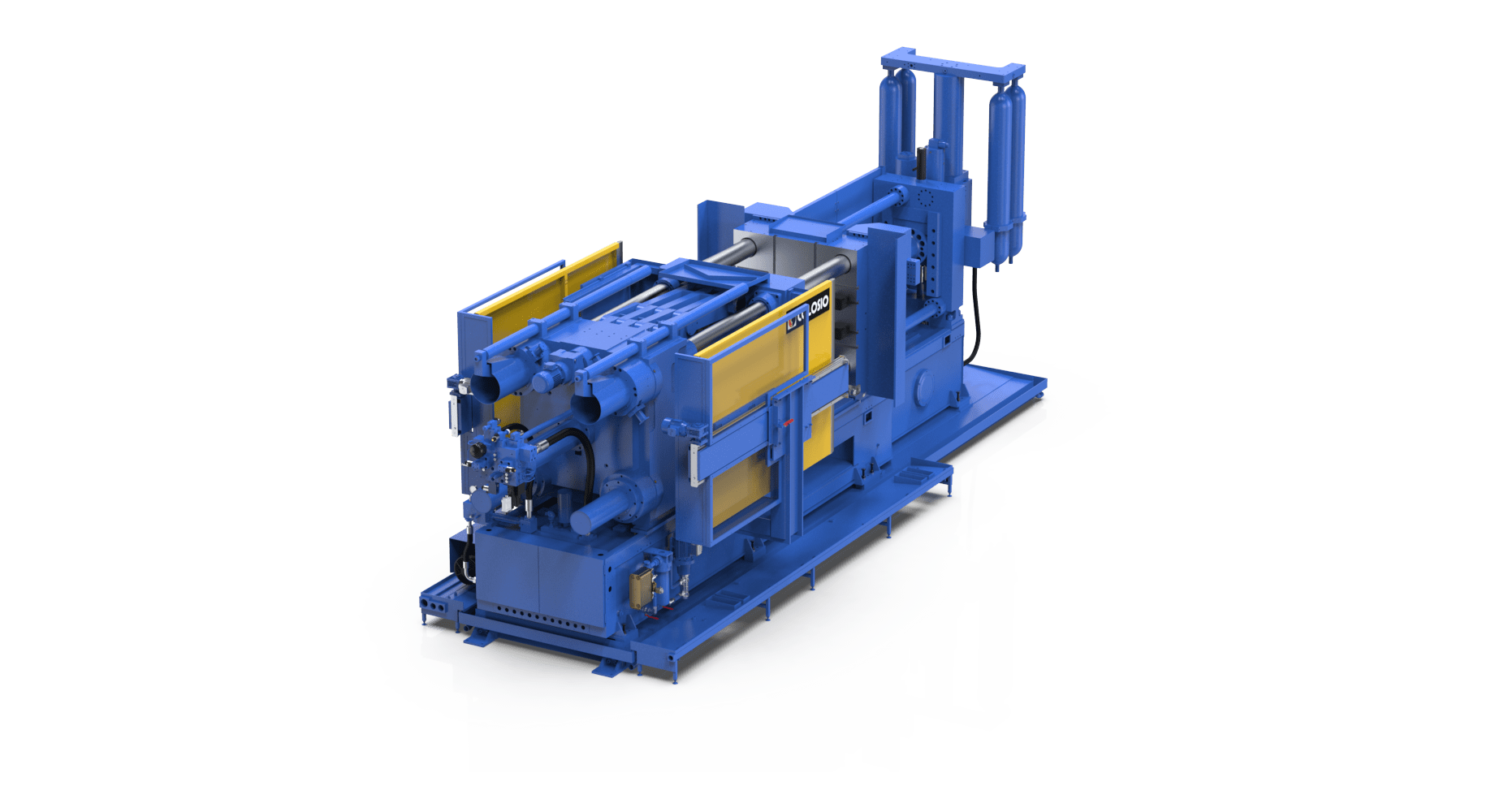

The aluminum, brass and magnesium die casting machines are available with the innovative GREEN LINE system, a new reference model of energy saving system for cold chamber machines.